The manufacturing industry is undergoing a profound transformation, thanks to the integration of cutting-edge technologies. In this article, we explore how technology is reshaping the landscape of manufacturing, increasing efficiency, reducing costs, and enhancing product quality.

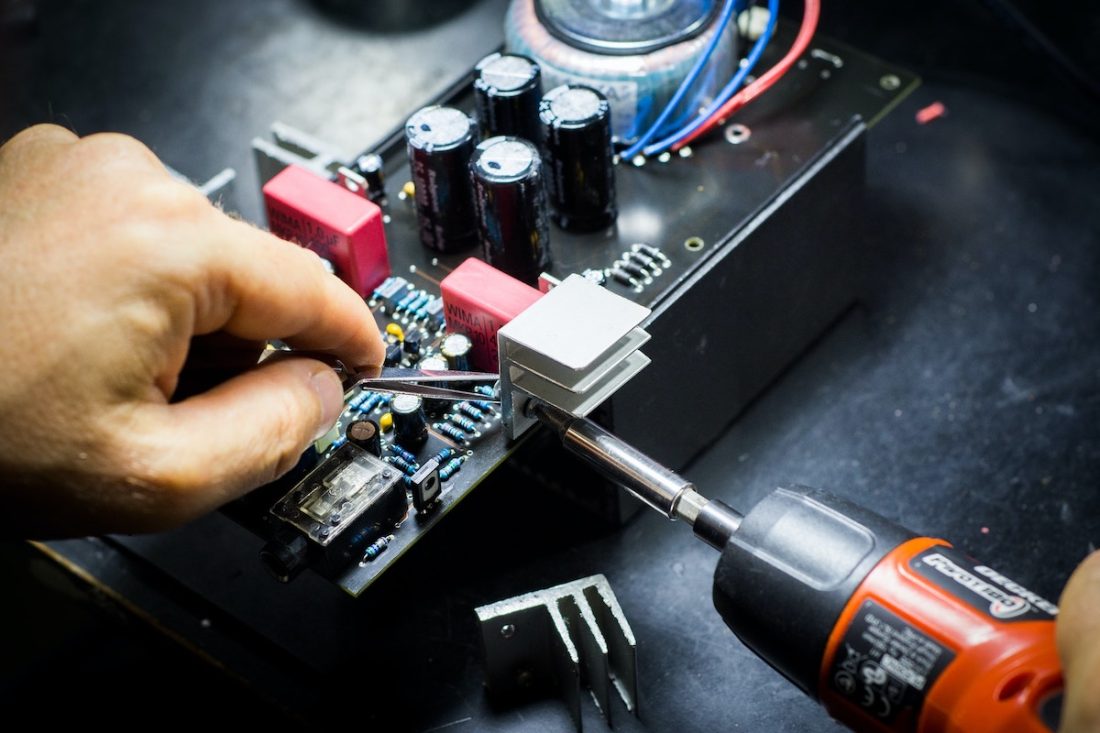

Automation and Robotics

Automation is at the forefront of the manufacturing revolution. Robots and automated systems are being used for a wide range of tasks, from assembly to material handling. They work tirelessly without fatigue, reducing errors and significantly increasing production rates.while playing https://www.casinosonline-canada.ca/casino-games/ and stand a chance to win big

Internet of Things (IoT)

IoT connects machines and devices, enabling manufacturers to gather real-time data about equipment performance and production processes. This data empowers decision-makers with insights for optimizing operations, predictive maintenance, and quality control.

Artificial Intelligence (AI)

AI has found its way into manufacturing, enhancing predictive maintenance and quality control. It can analyze massive amounts of data to predict when machines will fail, reducing downtime. Machine learning algorithms also improve product quality by identifying defects earlier in the production process.

3D Printing and Additive Manufacturing

The ability to create complex, customized parts with 3D printing is a game-changer. It reduces material waste, allows for rapid prototyping, and makes small-batch production economically viable.

Augmented Reality (AR) and Virtual Reality (VR)

AR and VR not only apply to video games and blackjack online gambling. These technologies are being used for training, maintenance, and assembly. Workers can access information through smart glasses, facilitating complex tasks and reducing errors.

Big Data and Analytics

Manufacturers can make informed decisions by harnessing the power of big data and analytics. They gain insights into production performance, supply chain management, and customer demand, allowing for better resource allocation and inventory management.

Cloud Computing

Cloud technology simplifies data storage, sharing, and collaboration. It reduces the need for extensive on-site infrastructure and promotes remote work. Manufacturers can easily scale their operations without hefty upfront investments.

Cybersecurity Measures

With greater connectivity comes a need for robust cybersecurity. Protecting sensitive data and intellectual property is critical. Manufacturers are investing heavily in security measures to safeguard their operations.

Energy Efficiency

Sustainability and energy efficiency are top priorities in modern manufacturing. Advanced technologies allow manufacturers to monitor and reduce energy consumption, minimizing their environmental footprint.

Supply Chain Optimization

Technology helps streamline the supply chain. Manufacturers can track materials and products from the source to the end user, reducing inefficiencies and costs.

Collaborative Robots (Cobots)

Cobots are robots designed to work alongside humans. They are used for tasks that require precision and strength, making human-machine collaboration seamless.

Enhanced Customization

Technology allows manufacturers to offer increased customization to customers. Through advanced manufacturing processes, products can be tailored to individual preferences, meeting the demands of a diverse consumer base.

Improved Maintenance Strategies

Predictive maintenance, powered by AI and IoT, reduces downtime and extends the lifespan of machinery. Manufacturers can plan maintenance activities more efficiently, reducing operational disruptions.

Reshoring

Advanced technologies enable the return of manufacturing to local markets. Automation and digitalization help make domestic manufacturing competitive, reducing reliance on overseas production.

Environmental Responsibility

Manufacturers are increasingly adopting eco-friendly practices. Advanced technologies, such as 3D printing, reduce material waste, and energy-efficient processes contribute to sustainable manufacturing.

Conclusion

Technology is ushering in a new era for the manufacturing industry. With automation, IoT, AI, 3D printing, and many other innovations, manufacturers are becoming more efficient, sustainable, and adaptable. As these technologies continue to evolve, the potential for improved product quality and reduced costs is immense. The future of manufacturing looks brighter than ever, driven by the relentless pursuit of technological advancement.